1 /

1

EDI Ultra-pure Water System

Description:

Electronics industry、Semiconductor industry、Microelectronics industry、Power plants (boiler feedwater for NOx)、Laboratories、Pharmaceutical factories、Medical-grade ultra-pure water, and other industrial sectors

-

EDI (Electrodeionization), also known as Continuous Electrodeionization Technology, is primarily used to replace traditional mixed bed technology.

In the EDI process, ionized substances are removed from the product water through the action of an electric field, facilitated by conductive materials, to achieve the production of high-purity water.

The Ultra-Pure Water Electrodeionization Technology System (EDI) represents a revolutionary invention in water treatment technology.

This technique utilizes high voltage generated by electrodes at both ends to induce the movement of charged ions in water.

By combining ion exchange resins and selective resin membranes, the process accelerates the removal of ions, thereby achieving water purification.

The electrical resistivity of ultra-pure water is a crucial indicator of its purity, with higher resistivity indicating lower ion concentrations and higher purity.The resistivity of EDI ultra-pure water can reach 18.2M – cm, meeting various demands for ultra-pure water.

Moreover, the hydrogen ions (H+) and hydroxyl ions (OH-) required for the regeneration of ion exchange resins are supplied by the dissociation of water under high pressure, eliminating the need for the addition of acid or alkali chemicals.

-

-

Influent and effluent water standards

-

System IntroductionEDI (Electrodeionization), also known as Continuous Electrodeionization Technology, is primarily used to replace traditional mixed bed technology.

In the EDI process, ionized substances are removed from the product water through the action of an electric field, facilitated by conductive materials, to achieve the production of high-purity water.

The Ultra-Pure Water Electrodeionization Technology System (EDI) represents a revolutionary invention in water treatment technology.

This technique utilizes high voltage generated by electrodes at both ends to induce the movement of charged ions in water.

By combining ion exchange resins and selective resin membranes, the process accelerates the removal of ions, thereby achieving water purification.

The electrical resistivity of ultra-pure water is a crucial indicator of its purity, with higher resistivity indicating lower ion concentrations and higher purity.The resistivity of EDI ultra-pure water can reach 18.2M – cm, meeting various demands for ultra-pure water.

Moreover, the hydrogen ions (H+) and hydroxyl ions (OH-) required for the regeneration of ion exchange resins are supplied by the dissociation of water under high pressure, eliminating the need for the addition of acid or alkali chemicals.

-

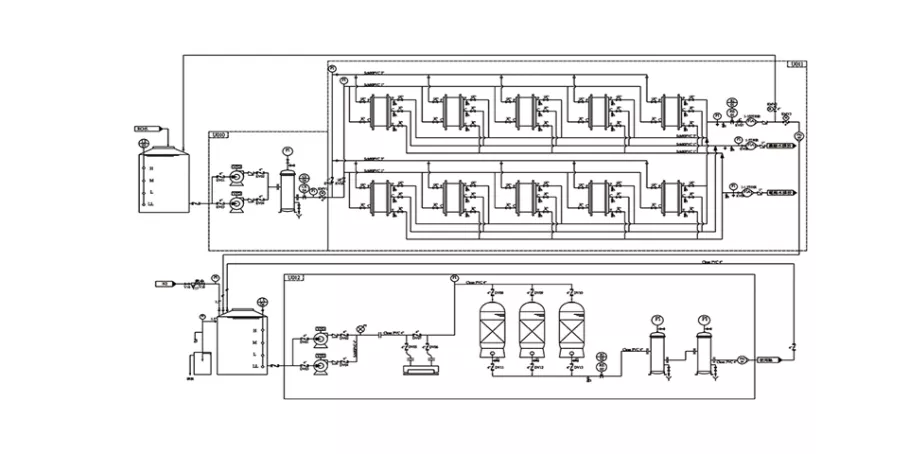

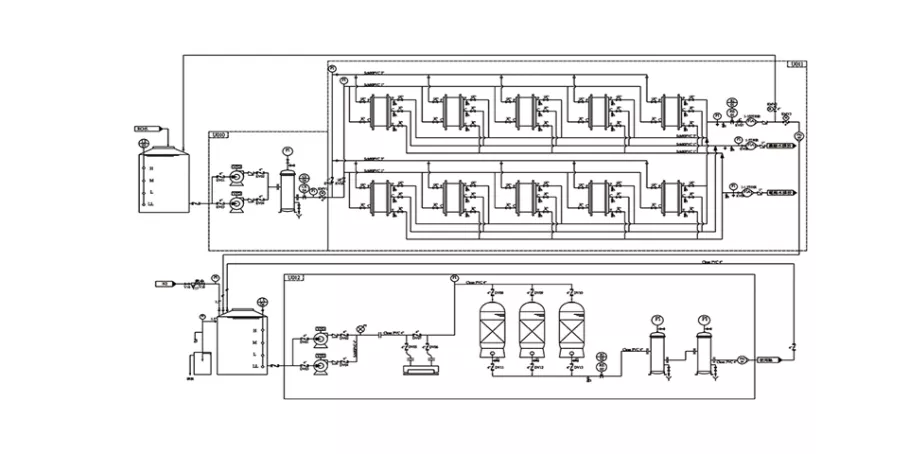

Process Flow

-

Specification Sheet

Influent and effluent water standards