1 /

1

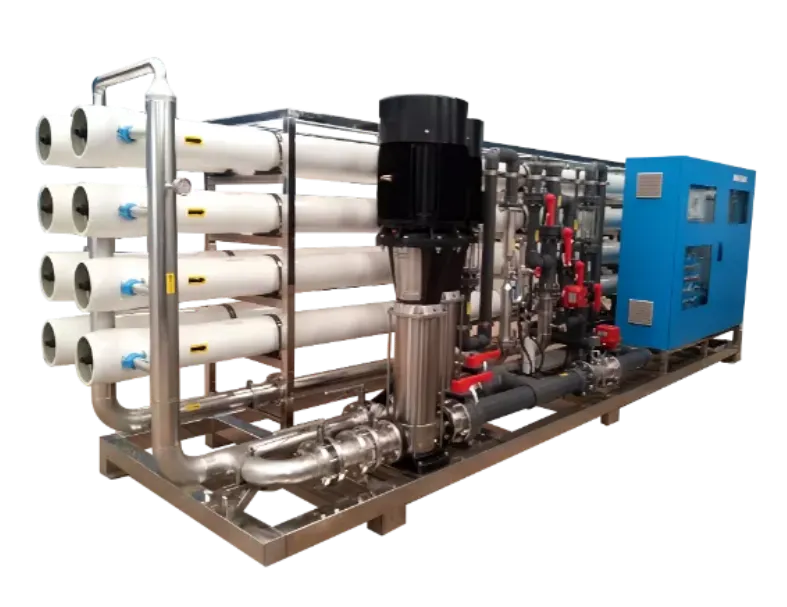

RO Reverse Osmosis System

Description:

The food industry、Chemical industry、Papermaking industry、Salt production industry、Pharmaceutical industry、Medical biotechnology industry、Biotechnology、Environmental protection engineering, and others

-

RO reverse osmosis technology is an efficient membrane separation technique that utilizes a semi-permeable membrane under pressure to effectively separate solvents and solutes in a solution. By applying sufficient pressure, the solvent (typically water) is forced through the reverse osmosis membrane, leaving behind pure solvent while isolating solutes. Reverse osmosis utilizes a pressure greater than the osmotic pressure of solutes to separate, purify, and concentrate solutions.

RO devices typically consist of pre-treatment units such as fine filters, granular activated carbon filters, and compressed activated carbon filters. These units are followed by a pump to pressurize the solution through a reverse osmosis membrane with pores as small as 1/10000μm (equivalent to 1/6000 the size of an Escherichia coli bacterium, or 1/300 the size of a virus). This process converts high-concentration water into low-concentration water, while effectively isolating a significant amount of impurities such as industrial pollutants, heavy metals, bacteria, and viruses, thereby meeting drinking water standards and hygiene standards.

RO (Reverse Osmosis) technology is currently the most effective water treatment method in terms of filtration efficiency. It can efficiently remove charged ions, inorganic substances, colloidal particles, bacteria, organic matter, and other contaminants from water. The purity of the water achieved through RO is nearly 100%, making it the optimal choice for drinking water.

-

-

-

System IntroductionRO reverse osmosis technology is an efficient membrane separation technique that utilizes a semi-permeable membrane under pressure to effectively separate solvents and solutes in a solution. By applying sufficient pressure, the solvent (typically water) is forced through the reverse osmosis membrane, leaving behind pure solvent while isolating solutes. Reverse osmosis utilizes a pressure greater than the osmotic pressure of solutes to separate, purify, and concentrate solutions.

RO devices typically consist of pre-treatment units such as fine filters, granular activated carbon filters, and compressed activated carbon filters. These units are followed by a pump to pressurize the solution through a reverse osmosis membrane with pores as small as 1/10000μm (equivalent to 1/6000 the size of an Escherichia coli bacterium, or 1/300 the size of a virus). This process converts high-concentration water into low-concentration water, while effectively isolating a significant amount of impurities such as industrial pollutants, heavy metals, bacteria, and viruses, thereby meeting drinking water standards and hygiene standards.

RO (Reverse Osmosis) technology is currently the most effective water treatment method in terms of filtration efficiency. It can efficiently remove charged ions, inorganic substances, colloidal particles, bacteria, organic matter, and other contaminants from water. The purity of the water achieved through RO is nearly 100%, making it the optimal choice for drinking water.

-

Process Flow

-

Specification Sheet