Direct-drive series installed on ISO 5211 platform specification valves (valves)

Professional certification

ISO 9001、CE、CSA、UL429、IP67

-

-

Direct-drive electric motor actuators need to be installed on ISO 5211 standard flat or butterfly valves

-

The UM/R series electric motor actuators are low-power, high-torque actuators

-

The entire housing is sealed with waterproof gaskets, achieving IP67 certification, suitable for outdoor environments

-

Smooth opening speed effectively avoids water hammer, extending the lifespan of pipeline components

-

UM/R series electric motor actuators can be equipped with top window or side viewing ports to inspect valve position, or controlled via wiring control boxes with indicator lights

-

IP67 waterproof rating

-

Housing components are made of materials such as "NYLON," known for high temperature resistance, acid and alkali resistance, and impact resistance

-

Aluminum alloy housing is available as an optional purchase

Optional Accessories-

Temperature controller

-

Non-electrical micro switch (up to 2 sets)

-

Heater (including overheat protector)

-

Proportional controller

-

On-site control

-

Relay

-

Potentiometer (VR set)

Precautions-

When operating manually or during maintenance, always turn off the power first to prevent component damage and hazards. When using manual operation, it is recommended to use a wrench (8mm opening) with a length not exceeding 10 cm. Turn gently; if it feels tight, check if the valve body is locked before proceeding. Do not use excessive force to turn, as this may damage internal components*Do not use other rods to rotate the handwheel, as this may damage the electric motor actuator and valve

-

After completing wiring work, check if the waterproof device (O-ring) is in place before tightening the casing. Ensure that the cable gland screws are securely tightened to prevent dust or rainwater ingress. (It is recommended that customer wiring should be a minimum of 6mm in diameter or larger.)

-

If two or more electric valves need to open or close simultaneously, install a relay for each valve. Do not connect them in series or parallel

-

When operating manually, ensure that the window pointer does not exceed the scale range to avoid damaging internal components. (For proportional controllers: variable resistor (VR) damage may occur.)

-

-

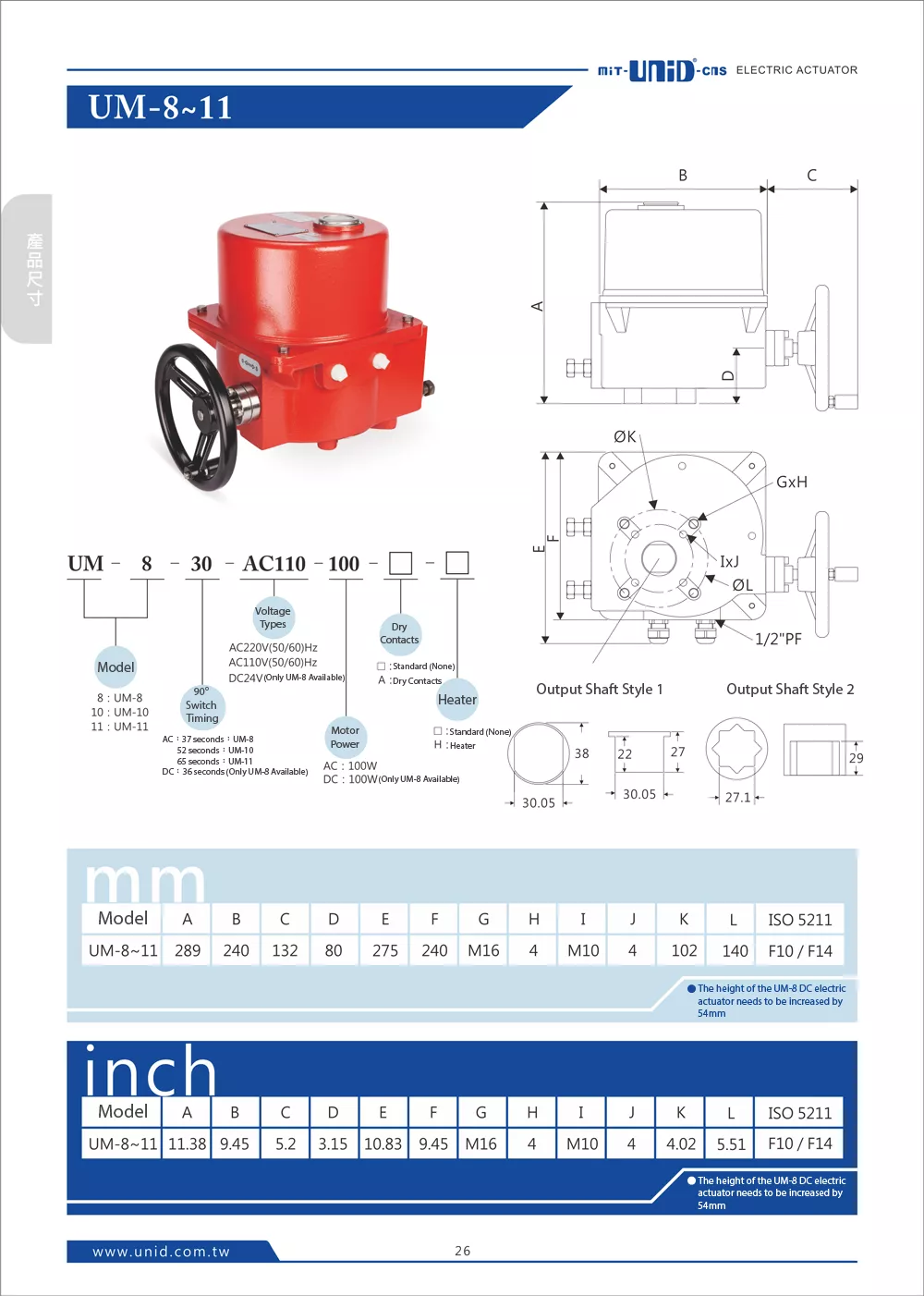

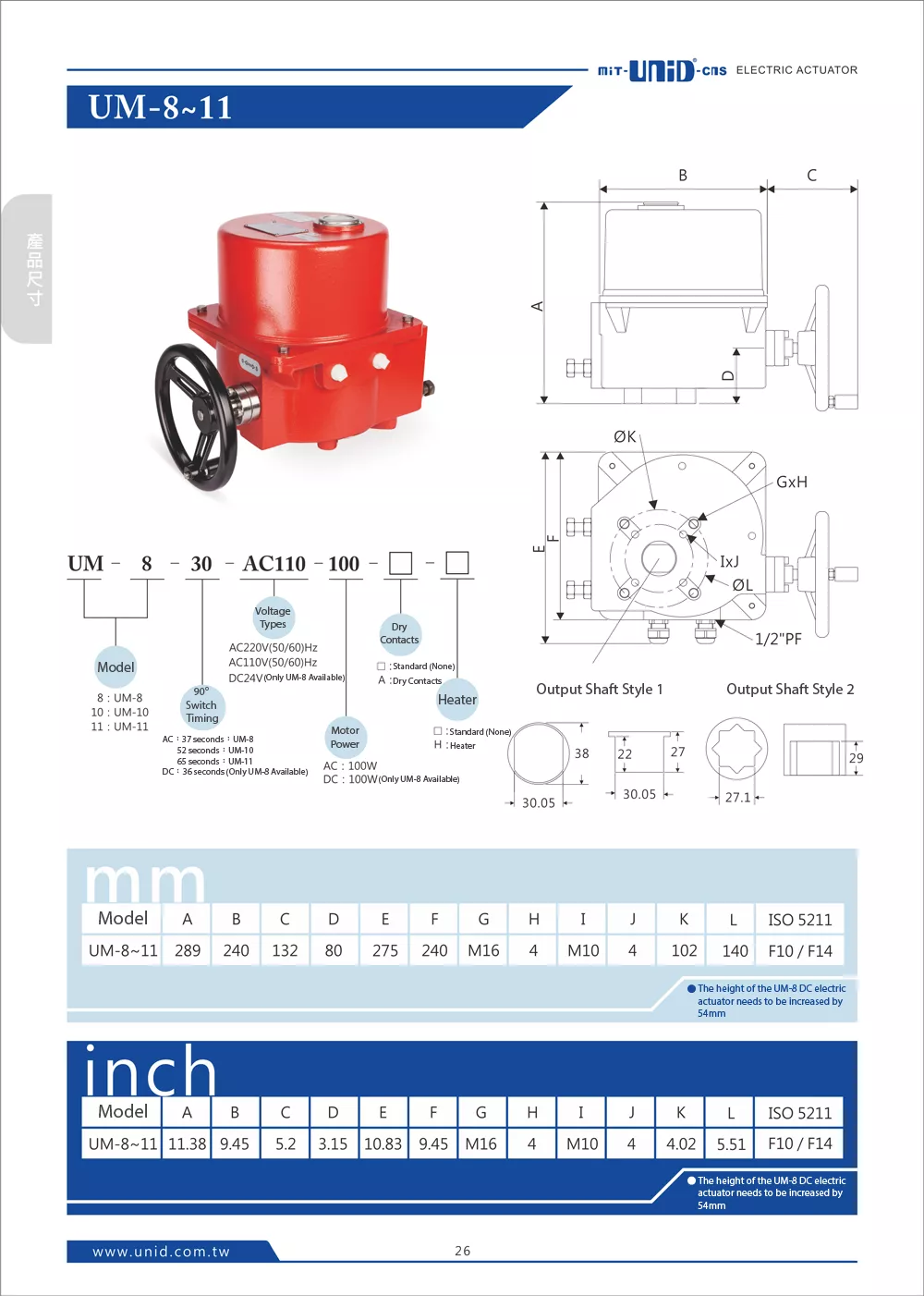

Weight28 kgManual deviceHandwheelFlange hole distance(ISO 5211)F10/F14

左右滑動看表格

左右滑動看表格Model Motor Power 90° Rotation Switch Time (sec) Torque Value(±5%)

kgf-cm

AC110V(60Hz)Torque Value(±5%)

kgf-cm

AC220V(60Hz)No-Load Consumption Current AC

100V~120VAC

200V~240VUM-8 100W 37 11038 9296 1.2A 0.6A UM-10 100W 52 12060 13500 1.2A 0.6A UM-11 100W 65 15000 14500 1.2A 0.6A  左右滑動看表格

左右滑動看表格Model Motor Power 90° Rotation Switch Time (sec) Torque Value(±5%)

kgf-cm

AC110V(60Hz)No-Load Consumption Current DC24V UM-8 100W 36 10000 0.7A

Rated voltage(special voltages available on request)-

AC 100V ~ 120V

-

AC 200V ~ 240V

-

DC 24V

-

-

Product Features Introduction

-

Direct-drive electric motor actuators need to be installed on ISO 5211 standard flat or butterfly valves

-

The UM/R series electric motor actuators are low-power, high-torque actuators

-

The entire housing is sealed with waterproof gaskets, achieving IP67 certification, suitable for outdoor environments

-

Smooth opening speed effectively avoids water hammer, extending the lifespan of pipeline components

-

UM/R series electric motor actuators can be equipped with top window or side viewing ports to inspect valve position, or controlled via wiring control boxes with indicator lights

-

IP67 waterproof rating

-

Housing components are made of materials such as "NYLON," known for high temperature resistance, acid and alkali resistance, and impact resistance

-

Aluminum alloy housing is available as an optional purchase

Optional Accessories-

Temperature controller

-

Non-electrical micro switch (up to 2 sets)

-

Heater (including overheat protector)

-

Proportional controller

-

On-site control

-

Relay

-

Potentiometer (VR set)

Precautions-

When operating manually or during maintenance, always turn off the power first to prevent component damage and hazards. When using manual operation, it is recommended to use a wrench (8mm opening) with a length not exceeding 10 cm. Turn gently; if it feels tight, check if the valve body is locked before proceeding. Do not use excessive force to turn, as this may damage internal components*Do not use other rods to rotate the handwheel, as this may damage the electric motor actuator and valve

-

After completing wiring work, check if the waterproof device (O-ring) is in place before tightening the casing. Ensure that the cable gland screws are securely tightened to prevent dust or rainwater ingress. (It is recommended that customer wiring should be a minimum of 6mm in diameter or larger.)

-

If two or more electric valves need to open or close simultaneously, install a relay for each valve. Do not connect them in series or parallel

-

When operating manually, ensure that the window pointer does not exceed the scale range to avoid damaging internal components. (For proportional controllers: variable resistor (VR) damage may occur.)

-

-

Specification SheetWeight28 kgManual deviceHandwheelFlange hole distance(ISO 5211)F10/F14

左右滑動看表格

左右滑動看表格Model Motor Power 90° Rotation Switch Time (sec) Torque Value(±5%)

kgf-cm

AC110V(60Hz)Torque Value(±5%)

kgf-cm

AC220V(60Hz)No-Load Consumption Current AC

100V~120VAC

200V~240VUM-8 100W 37 11038 9296 1.2A 0.6A UM-10 100W 52 12060 13500 1.2A 0.6A UM-11 100W 65 15000 14500 1.2A 0.6A  左右滑動看表格

左右滑動看表格Model Motor Power 90° Rotation Switch Time (sec) Torque Value(±5%)

kgf-cm

AC110V(60Hz)No-Load Consumption Current DC24V UM-8 100W 36 10000 0.7A

Rated voltage(special voltages available on request)-

AC 100V ~ 120V

-

AC 200V ~ 240V

-

DC 24V

-