1 /

1

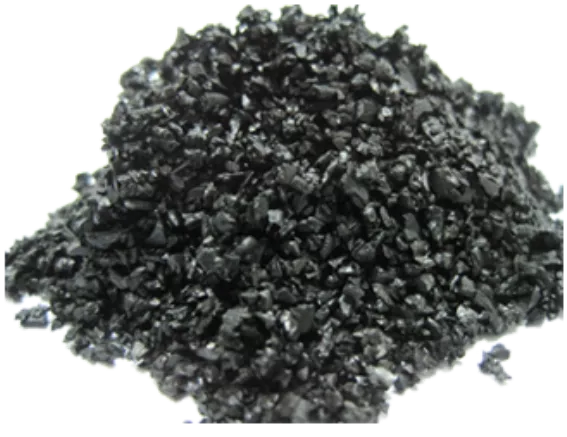

Coconut Shell Activated Carbon

Description:

Application Range

Refineries, petrochemical plants, food processing industries, steel mills, textile factories, dyeing facilities, plastic processing plants, automobile factories, wastewater treatment plants, water purification plants, filter equipment manufacturers, electronics industry, semiconductor manufacturing, and various other industries utilize activated carbon extensively.

Refineries, petrochemical plants, food processing industries, steel mills, textile factories, dyeing facilities, plastic processing plants, automobile factories, wastewater treatment plants, water purification plants, filter equipment manufacturers, electronics industry, semiconductor manufacturing, and various other industries utilize activated carbon extensively.

-

Plasma-like coconut shell activated carbon is derived from specific coconut shell coal, known for its microporous structure. According to a research report from the University of South Australia, coconut shell activated carbon exhibits a high proportion of primary micropores, with pore diameters less than (<2 nm) and ranging between (0.3-0.7 nm). This characteristic gives it excellent adsorption capabilities for small molecule substances, with an iodine adsorption capacity of >1000 mg/g.。

With a neutral pH and extremely low water-soluble content, it is particularly suitable for use in drinking water purification systems.

Coconut shell activated carbon finds extensive application in environmental engineering processes such as wastewater (air) treatment, including heavy metal ion removal from electroplating, dyeing, and general industrial wastewater. It is effective in removing trace organic compounds from drinking water, such as phenols, chloroalkanes, dyes, and odorous molecules. -

Moisture (after packaging)<4%Ash content<3.0%Carbon tetrachloride adsorption>60%Iodine adsorption1000mg/gHardness>99%Water-soluble content<0.2%pH value)9-10

Typical CharacteristicsIodine Valuem2/g1100>Total Surface Area (Nitrogen, BET Method)m2/g1050Apparent Density (Hardness >99%)g/cm30.48-0.50Mesh Size Distribution,6 ×12 meshwt.%90-95Packaging: 50L / 25KG / bag

Activated Carbon Treatment: Activated carbon undergoes high-temperature activation to maximize pore development, enhancing its adsorption and purification capabilities.

-

Product Features IntroductionPlasma-like coconut shell activated carbon is derived from specific coconut shell coal, known for its microporous structure. According to a research report from the University of South Australia, coconut shell activated carbon exhibits a high proportion of primary micropores, with pore diameters less than (<2 nm) and ranging between (0.3-0.7 nm). This characteristic gives it excellent adsorption capabilities for small molecule substances, with an iodine adsorption capacity of >1000 mg/g.。

With a neutral pH and extremely low water-soluble content, it is particularly suitable for use in drinking water purification systems.

Coconut shell activated carbon finds extensive application in environmental engineering processes such as wastewater (air) treatment, including heavy metal ion removal from electroplating, dyeing, and general industrial wastewater. It is effective in removing trace organic compounds from drinking water, such as phenols, chloroalkanes, dyes, and odorous molecules. -

Specification SheetMoisture (after packaging)<4%Ash content<3.0%Carbon tetrachloride adsorption>60%Iodine adsorption1000mg/gHardness>99%Water-soluble content<0.2%pH value)9-10

Typical CharacteristicsIodine Valuem2/g1100>Total Surface Area (Nitrogen, BET Method)m2/g1050Apparent Density (Hardness >99%)g/cm30.48-0.50Mesh Size Distribution,6 ×12 meshwt.%90-95Packaging: 50L / 25KG / bag

Activated Carbon Treatment: Activated carbon undergoes high-temperature activation to maximize pore development, enhancing its adsorption and purification capabilities.